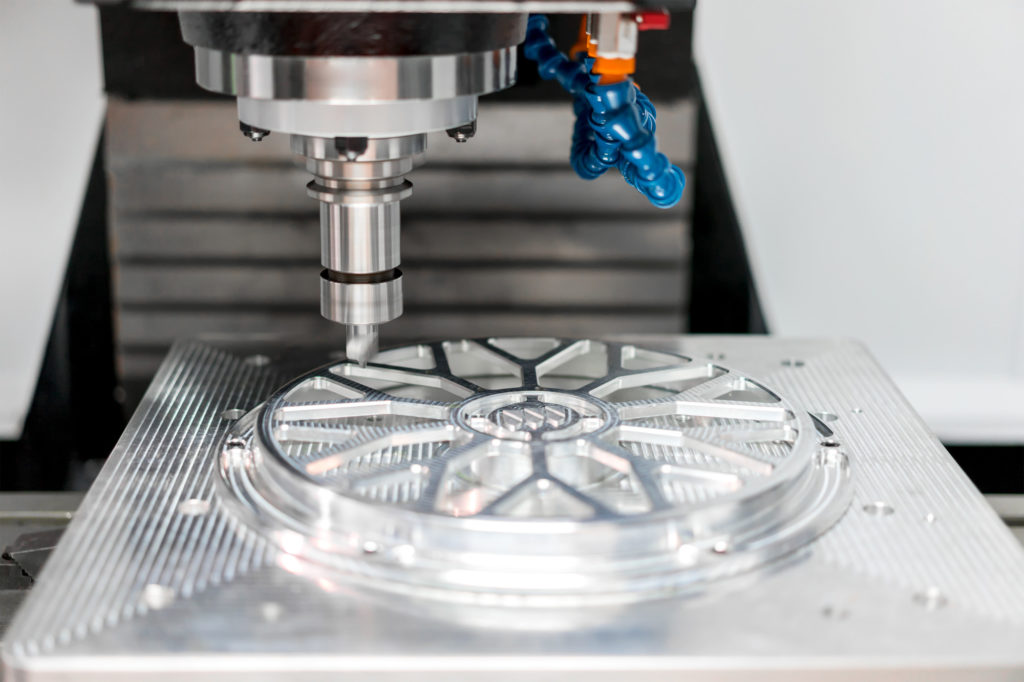

Buy The Rapid Tooling Of Best Quality From Good Supplier

The rapid tool is a service that was made to provide Molded parts that are real injected in a short period of time. Here its speed is not only a point of discussion but the way of designing also plays a very important role and you can get the desired design just by using rapid tooling in the right manner. Using such type of tool can not only reduce the time of production but also decrease the cost of the product so that manufacture can get huge benefits by using rapid tooling. If you know the right and proper usage of these tools then you can use it for a long period of time without seeing any type of problem in the machine.

What is the difference between rapid direct and indirect tooling?

This is the two categories of rapid tooling where you can use both of them for different reasons and output. Indirect Rapid tooling is used for producing die ort mold while direct tooling is the method that provides actual molds. You can choose any of these according to your choice and requirement to make your work easier than before by reducing the cost of production. If want to get actual mold then you have to use direct tooling so that this will improve the quality of the product in less time.

Why use for molding soft materials?

If you are looking for the type of tool that will help in molding soft materials like non-metallic material then you should know about Soft rapid tooling. These are the best one if want to mold soft materials while if you are looking for the type of tool that will help you in molding all hard and metallic things like steel or aluminium then you should know about hard tooling. So don’t get confused and use the one that meets with your need and type of material that you want to mold. While choosing machine people should know each and everything about their way of production and what type of tool is needed otherwise you will not get an appropriate tool for production.

How to find the best rapid tooling?

Looking for the best rapid tooling then you should know some of the important factors that play a very important role in selecting the partner for that you have to follow the following things-

- The price- this is the biggest factor that people look at first so that it will be easy to decide the budget. If you want to get a good product then try to select the machine that has all the necessary features at good or affordable rates.

- Quality of machine- the quality of the machine must be good otherwise you have to invest again in the same tool and which becomes very costly for doing any type of production.

- Reassurance- you can search each and everything on the net so that it will be easy to get the guidance of all things related to molding.

Hence, if you want to buy rapid tooling then try to do a proper online survey and then buy the best and required one.